The aluminum CTP substrate board can divided into metal plates and polyester plate, metal plate refers to aluminum sheet, high resistance to printing, suitable for long version printing.

Computer to plate:directly from the computer to the printing plate, that is, offline direct plate making. Originally developed by photographic direct plate, all computer controlled laser scanning images were developed, but printed by developing, fixing, and other processes. This technique eliminates the medium of film, which transforms text and images into numbers, and reduces the quality loss and material loss in the intermediate process. Usually, CTP is this type.

Computer to Press:directly from computer to printing machine, that is, machine direct plate making. The computer controlled laser beam outputs the graphic information directly to the printing plate, and the printing plate is mounted on the cylinder. This kind of printing plate can only be used once, and the graphic information can be recorded.

The Computer to Paper/Print:computer goes directly to paper or printing, that is, direct printing technology.

Computer to Proof:a computer direct proofs, namely color digital proofing.

PS CTP sheet metal with aluminium substrate including quantitative indicators of aluminium substrate chemical composition, temperature and baking plate mechanical properties, thickness and width accuracy, surface roughness of aluminum substrate, burr and plate, these indexes in different degrees in relation to the PS CTP Substrate and board material production quantity.

The CTP board base uses the aluminum plate base alloy has 1050, 1060, 1070 and so on, at present the most commonly used is 1050 alloy, its chemical composition standard follows:

| Alloy | Al | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | The others | |

| 1050 | Min | 99.5 | 0.05 | 0.2 | |||||||

| Max | 0.2 | 0.4 | 0.03 | 0.03 | 0.03 | 0.05 | 0.02 | 0.03 | 0.03 | ||

| 1060 | Min | 99.6 | |||||||||

| Max | 0.25 | 0.35 | 0.03 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | |||

| 1070 | Min | 99.7 | |||||||||

| Max | 0.20 | 0.25 | 0.03 | 0.03 | 0.03 | 0.07 | 0.03 | 0.03 |

1. the internal components of PS CTP Substrate, that is, with the production of CTP board of the aluminum alloy containing trace metal elements and the content of the species. The market is the best use of PS CTP Substrate on 1050, added mass percentage of 0.15%--0.3% active elements magnesium, special metal content after adjusting the proportion of the more reasonable, the PS CTP Substrate has good mechanical properties and can significantly improve the electrolytic adaptability, improve the response sensitivity of sand to electrolysis no, strengthening treatment can form a fine layer of uniform sand.

2.The process control of the aluminum alloy base processing project, the special metal elements added are more evenly distributed in the aluminum body, so as to make the electrolytic sand fine and uniform. In this regard, the CTP board of the aluminum plate used for hot rolling of square ingot, first homogenization heat treatment.

The quality tracking of the chemical composition of the aluminum PS CTP Substrate is one of the important parameters to ensure the quality of the raw material. The common test method is the correction curve method of ICP atomic emission spectrometry.

CTP plates are available manually, semi automatically, fully automatic, and automatic positioning and punching devices, which require a certain stiffness of the plate. If the plate base is too soft and the stiffness is poor, it is easy to bend and affect the use of the upper plate. The PS CTP Aluminum Substrate is too hard and it is not easy to be leveled. Therefore, the aluminum plate used in the CTP plate must have good mechanical properties.

| Alloy Temper |

Direction | Room Temperature | Baking Temperature (280¡æ,4min) | Baking Temperature (280¡æ,10min) | ||||||

| Yield Strength Rp 0.2 (Mpa) | Tention Strength | Elongation A50% | Yield Strength Rp 0.2 (Mpa) | Tention Strength Rp 0.2 (Mpa) | Elongation A50% | Yield Strength Rp 0.2 (Mpa) | Tention Strength Rp 0.2 (Mpa) | Elongation A50% | ||

| Rp 0.2 (Mpa) | ||||||||||

| 1A25 H18 |

Horizontal | 150-190 | 170-205 | 2.0-2.5 | 130-178 | 140-190 | 2.0-3.0 | 154 | 163 | 2.7 |

| longitudinal | 155-205 | 170-205 | 1.5-5.5 | 140-170 | 160-180 | 2.0-4.0 | 148 | 1544 | 2.7 | |

| 1060 H18 |

Horizontal | 160-190 | 170-200 | 2.5-3.0 | 130-135 | 140-150 | 2.0-2.5 | 150 | 164 | 2.2 |

| longitudinal | 170-195 | 180-200 | 2.5-3.0 | 130-145 | 145-150 | 2.5-3.0 | 145 | 162 | 2.7 | |

| 1050 H18 |

Horizontal | 170-190 | 180-205 | 2.0-2.5 | 165-180 | 170-190 | 3.0-3.5 | 166 | 185 | 2.7 |

| longitudinal | 170-180 | 180-190 | 2.0-2.5 | 145-165 | 150-180 | 3.0-3.5 | 162 | 170 | 3.2 | |

The main indexes of the geometric properties of the aluminum sheet base are the width, thickness, ratio, arrogance, roughness and edge burr of the plate base, and the specific control range is shown in the table:

| Width/mm | Thickness/mm | Roughness | ||||

| Size | 400--1030 | 1031---1650 | ¡Ü0.35 | >0.35 | Frant | Both sides |

| Tolerance | ¡À0.3 | ¡À0.5 | ¡À0.005 | ¡À0.007 | ¡À0.2¡À0.1 | ¡Ü20 |

At present, there are two main types of PS CTP plate making machine market, which are drum type laser scanning method, plate making process and inner drum laser scanning method. The outer drum laser scanning method is to make the plate fixed outside the roller, when making plate with the drum at the same time high speed rotating, heat sensitive CTP board is used outside drum laser scanning way plate making. The inner drum laser scanning method is to place the plate on the inside of the drum. When the plate is made, the plate is stationary and the laser head is scanned at high speed. The laser CTP plate making machine adopts the inner drum laser scanning method. Plate making mechanism version of the speed, cut automatic version, automatic positioning, drilling, so the CTP board of the geometric requirements are very strict. Therefore, the dimensional quality of the aluminum base must be ensured, including the thickness of the plate base, the width of the aluminum roll and the uniformity of the plate base.

The thickness of the aluminum sheet used for CTP plates is commonly found in 0.15mm, 0.30mm, 0.40mm, and the thickness of 0.20mm and 0.24mm is the most used in japan. The control range of thickness is generally divided into two steps, namely a thickness of less than or equal to 0.35mm, the range of error allowed is +/-0.005mm; the thickness is more than 0.35mm, the range of error allowed is +/-0.0075mm, the longitudinal and transverse thickness tolerance and aluminium substrate should be less than or equal to +/-0.005mm. is the most commonly used 0.275mm. thick aluminum plate base plate, the stiffness will be better that is not easy to crease. But in order to reduce costs, the thickness of the aluminum sheet base will be controlled at the lower limit of the index.

The CTP board on board width, length and squareness of requirements is very high, because it directly affects the use of the customer, if the size deviation is too large, on the one hand, will lead to unacceptable and rejected platemaker; on the other hand, the effect of color, blurred print patterns. In addition, from the cost considerations, China plate production and some do not install the on-line cutting plate device, so the width tolerance less than +/-0.5mm aluminum coil, the best without tolerance, in order to avoid online piece adjusting and cutting edges are not allowed to question.

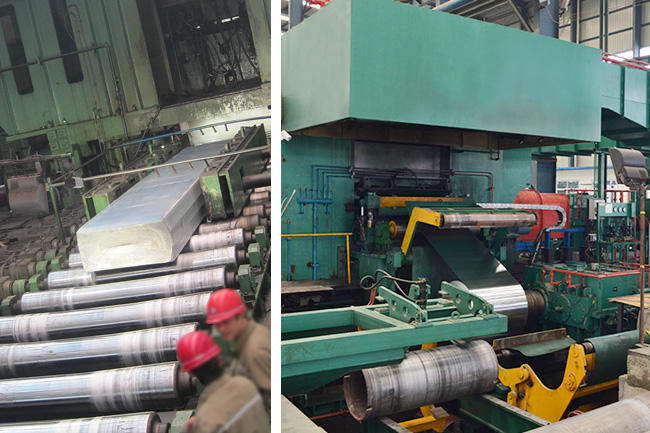

There are two ways to produce Aluminum PS/CTP Substrate: casting, rolling, cogging and hot rolling, two ways. The casting rolling method has low cost, but it also has certain problems in ensuring the smoothness and smoothness of the aluminum surface, while the hot rolled ingot is finely milled with fine surface smoothness and finish.

The production of PS CTP aluminum Substrate mainly includes: casting, hot rolling, cold rolling, finishing and heat treatment of the five processes. The characteristics of each process in the production process are as follows:

At present, the alloy used on PS CTP Substrate is mainly 1050, 1060, 1070, and the self-made alloy grade is adjusted on the basis of trace elements.

Because the CTP electrolysis sand request is more precise and even, so it is necessary to add elements in the aluminum body, cut evenly. Therefore, it is necessary to homogenization heat treatment of flat rolled ingot used for hot rolling of CTP aluminum base material.

Hot rolled coil pretreated, the coil car to the uncoiler was wearing, head through the rolling mill, roll down from the wrapper in the help, the number of ring winding after the wrapper exit, mill start or speed rolling, rolling mill will be finished when the automatic deceleration to wear speed finally, the winding up device, a coil discharge car, unloading after weighing bale out of a thick, rolling. The production of PS CTP Substrate requires intermediate annealing. Generally, after a cold rolling period, intermediate annealing is needed, and the annealed coil is cooled and rolled to the finished product thickness.

Under ordinary circumstances, the ordinary printed board base does not need to return the product, and the PS CTP Substrate adopts the nitrogen protective gas annealing treatment under the specific condition.

After the milling face, the ingot is heated in the ingot heating furnace and then uniformly heated, and then transferred to the hot roller table for reversible rolling. When rolled to about 100--150mm thick, the end and end of the heavy shear is rolled. When the thickness of the process is rolled to the hot finishing mill, the product is rolled to the finished thickness (2mm--10mm). In order to ensure the mechanical properties of the final product, the thickness of the hot rolled coil is generally about 4.0mm.

The PS CTP Substrate has high requirements on the surface quality and accuracy of the products and the flatness of the strip. The requirements for the finishing equipment are equally strict, especially the straightening machine is the most critical part. At present, the production of PS CTP plate base has begun to use the best straightening effect of pure tensile machine, and its finished plate flatness reached 31 times, is the traditional stretch bending straightening unit can not be stable. The equipment is also the key equipment for developing and improving the industrial chain of high and new technology, digital printing technology and high definition plate making system.

Quality Control of PS CTP Aluminum substrate:

PS/CTP printing plate used for high quality color printing,PS / CTP plate making machine with plate scanning FM / am or FM hybrid screening technology, the base plate grain value generally in 0.45--0.55um, to achieve reduction of fine lines and dot, in addition to electrolytic process and production of the factory but also with aluminum body the surface quality and surface roughness have a direct relationship. Generally, the greater the surface roughness of the aluminum base, the larger the electrolytic plate, because the roughness is accumulated. The thicker the sand mesh, the worse the reducibility of the dot and reticle. The roughness of PS CTP Aluminum substrate should be controlled in 0.20um+/-0.10um, Rt or 3um, otherwise it is difficult to make grain layer thinner. In addition, the internal and external defects of thePS CTP Aluminum substrate itself will also affect the quality of electrolytic grinding plate, such as rolling line, metal stripe, oil stain pressing and the surface of aluminum plate being oxidized. Although, in the internal defect is not serious, can be improved by adjusting the parameters to eliminate electrolytic corrosion, but if the apparent substrate is of poor quality, no enhancement electrolysis cannot be eliminated the layout of the defects, lead to rough sand.

The plate shape of the PS CTP plate is directly affected by the plate shape of the aluminum plate used. The plate shape of the aluminum plate refers to the flatness of the aluminum substrate. The defects of the aluminum plate are due to the uneven extension of the longitudinal direction of rolling in the width direction, resulting in the internal stress, resulting in the double edge wave, unilateral edge wave and middle drum of the Aluminum substrate. PS CTP sheet production team of aluminium substrate requirements are:

1) strip roughness, the number of waves in each meter length of not more than 3, each wave height shall not be greater than 3mm;

2) in strip free, does not allow any visual visible falbala, middle wave.

Type PS CTP plate requirements are a little flat is not allowed, because most of the CTP device using scanning imaging, unlike PS print is the use of vacuum method can make the layout and film sealing, such as plate flatness, effect of laser imaging quality and CTP platemaking machine loading problem.

In the CTP board of the total production of aluminum substrate, the apparent impact on the quality of the production and quality of the final product is the largest, most control is not good, not only no specific quantitative indicators, but also because the production line is different, have different defects. Therefore, to ensure the quality of CTP plates, the apparent quality of aluminum base is the prerequisite. The apparent quality of aluminum sheet base is divided into two parts: one is the appearance quality of winding packaging; two is the apparent quality of aluminum base.

Generally, when receiving aluminum substrate, the appearance should not have these defects: outer ring damage, creases, scratches, dents, stacking damage, banding marks, and so on. Usually aluminum substrate down visual inspection machine before the Standing Volume actually ignored, this part of the examination can not be ignored, otherwise it will lead to burn off, Kika aluminum board, or even damage the coating dies and other equipment, causing production disruptions, causing unnecessary economic losses.

There are two kinds of packing of aluminum substrate: vertical and horizontal, either way, after unpacking must be checked on both sides of section quality, such as the <2mm >2mm section should be staggered and staggered easily lead to folding, on both sides of face have bumps and depressions, these problems once discovered, should be treated first in the machine before, because these will damage damaged position of aluminium based nominal thickness increase, there may not be Tsui by coating gap, eventually coating scratches caused tear strip Tsui and broken belt; and the shaft core is loose, there is no surface oxidation.

PS CTP plate production process, the common aluminum plate based on the surface defects are: over scratch, black strip, rolling lines, weaving lines, non-metallic indentation, metal press, imprint, mechanical damage several. Typical internal quality problems mainly lie in uneven chemical composition, coarse structure, abnormal shape and size of compound, etc.. These defects are extremely demanding for surface quality, and the high-end PS CTP board base required for electrolytic etching of sand grains is indeed a fatal defect.

1103 No.14 Shangwu Outer Ring Rd, New District, Zhengzhou, China.

Tel: +86-371-65621391 Fax: +86-371-65621393 Mobile: +86-13938245529